How to develop a Risk-based manufacturing process and control strategy using Quality by Design

In recent years, there has been a growing interest in enhancing the quality and safety of medicinal products while reducing costs through structured development and manufacturing approaches. Regulatory acceptance of science-based approaches fosters flexibility, allowing the implementation of well-established solutions from chemical and food engineering. One of the approaches is Quality by Design (QbD).

Process optimization using Quality by Design

Traditionally, the pharmaceutical and biopharmaceutical industries have not been the forerunners of innovative engineering solutions. For decades, a regulatory framework centered on testing quality into the product, known as Quality by Testing (QbT), has governed pharmaceutical manufacturing. In contrast, other fields of processing and related manufacturing sciences have successfully implemented sophisticated technologies to increase process- and product understanding.

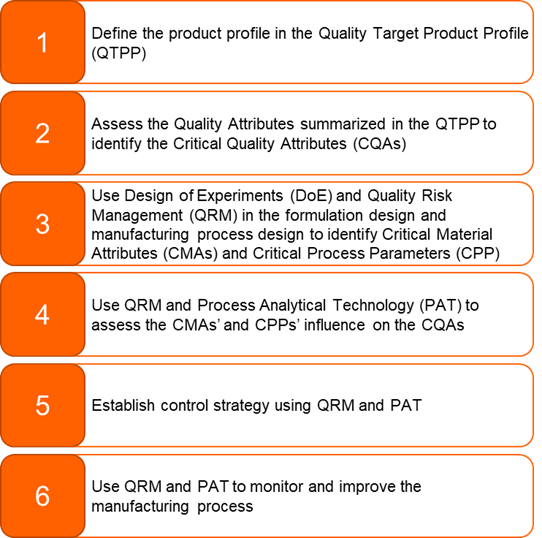

The concept behind QbD is to build quality into the product and processes through a systematic scientific and risk-based approach to product and process design. A collection of tools, including Design of Experiments (DoE), Quality Risk Management (QRM) and Process Analytical Technology (PAT), contribute to organize the formulation development process and manufacturing development process. Building quality into the product and processes is done by identifying and control Critical Quality Attributes (CQAs), Critical Material Attributes (CMAs), and Critical Process Parameters (CPPs). It provides the ability to systematically design a robust formulation and manufacturing process. The integration of the mentioned parameters/tools in the QbD approach boosts product and process knowledge. It enables concurrent development of the manufacturing process alongside formulation design.

Product and process development

The QbD based product development begins with defining the expectations of the product in terms of quality, efficacy, and safety. These expectations are summarized in the Quality Target Product Profile (QTPP), which defines the product profile. Critical Quality Attributes (CQAs) are outlined from the Quality Target Product Profile and the CQAs’ acceptance criteria define the product quality expectations.

Understanding CQA acceptance criteria facilitates a structured development process linked to CQAs and QTPP. Identifying and assessing Critical Material Attributes in formulation development and Critical Process Parameters in manufacturing design form the foundation. These interdependent factors establish a robust product, manufacturing process, and control process, ensuring consistent product quality.

What are the opportunities with QbD?

QbD implementation in product and process development ensures predictability, efficiency, cost-effectiveness, fewer interruptions, reduced product failures, and enhanced scalability. At the same time, QbD leads to a library of advanced solutions that will enhance the benefit from QbD. A well-defined QbD manufacturing process combined with Process Analytical Technology (PAT) enables a shift from batch to Continuous Manufacturing (CM).

This enhances manufacturing agility, requiring less infrastructure, space, and staff, enabling increased production volume without current scale-up obstacles. It will ensure a cost-effective production requiring less investment. A deeper look into the capabilities of QbD, PAT, and CM will be the natural step from here.

Curious to know more? Read other articles here or visit our LinkedIn Page here.

Jakob Rasmussen

Consultant

Jakob Rasmussen supports clients in the Pharmaceutical industry with implementation of global, harmonized quality processes and IT systems. He specializes in analyzing and optimizing processes, validation, developing quality documentation (GxP and GMP), implementing process improvements, IT and working in a GMP environment. Jakob has a strong academic background within Pharmaceutical Sciences and holds a Master of Science in Pharmaceutical Sciences.